Floor flatness measuring device

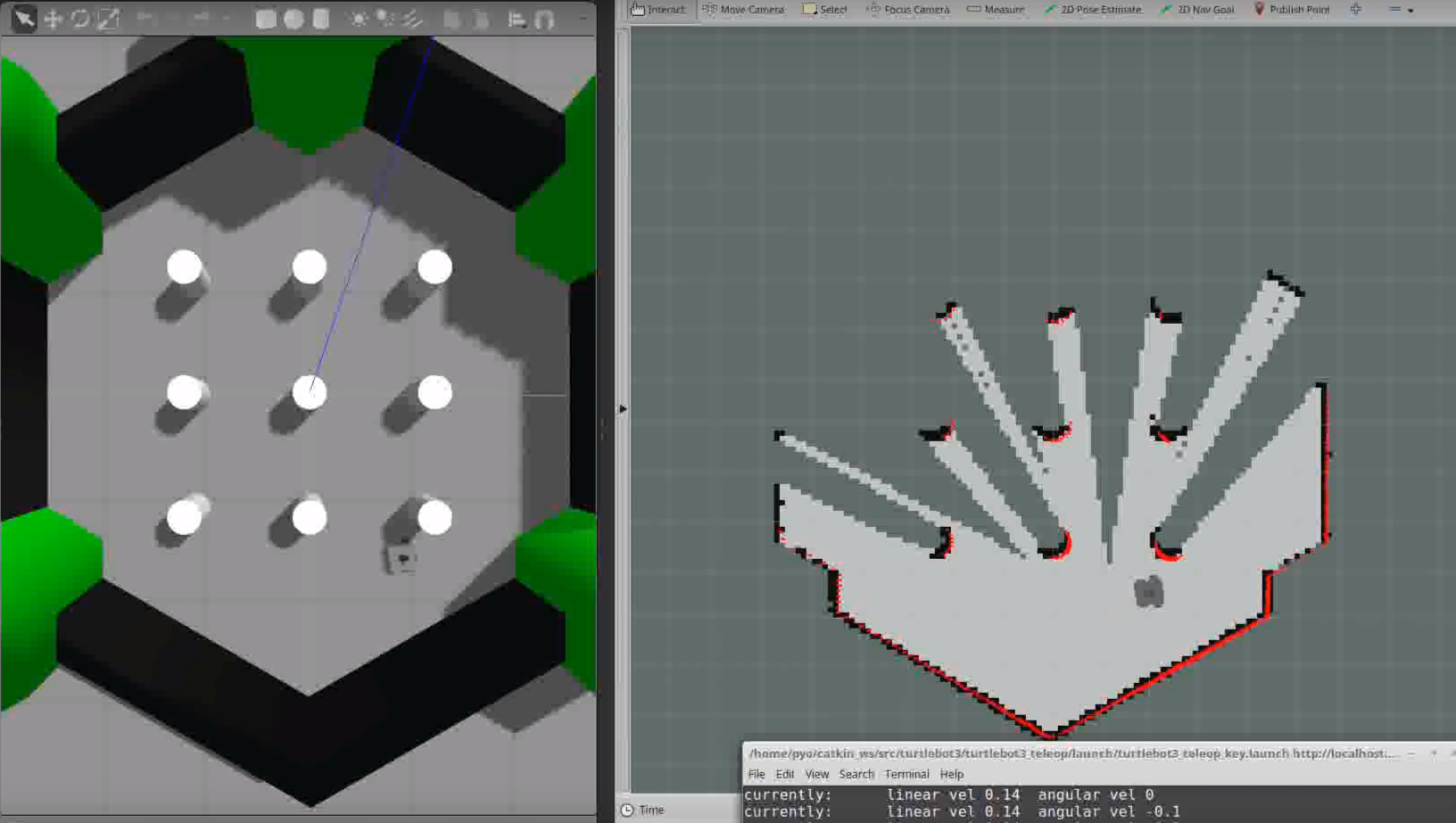

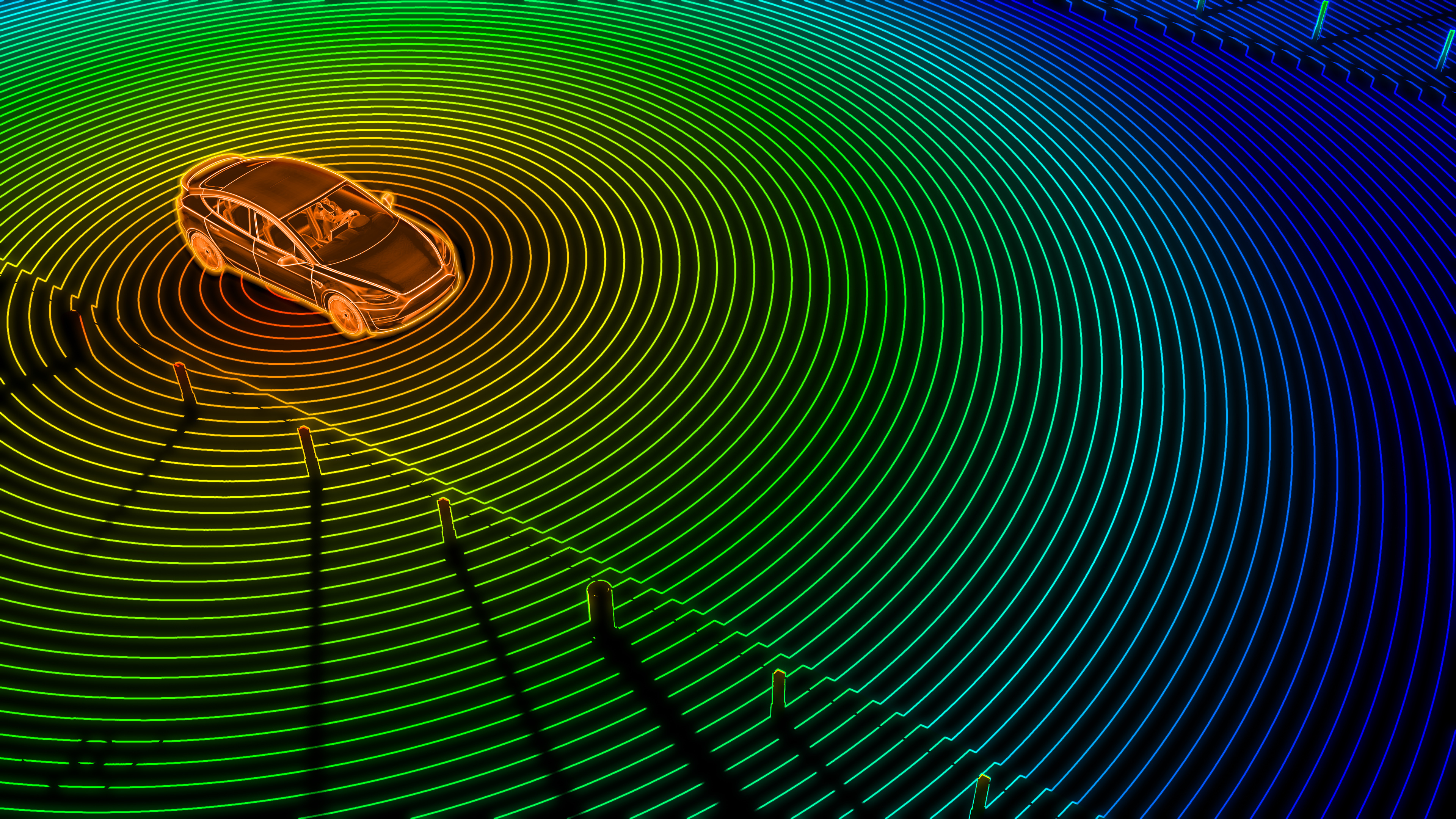

To solve the floor flatness problem on construction sites, I have been making device to check the flatness level. This is an ongoing project that converges technologies including LIDAR and SLAM.

My Role

Main developer

- Analyze requirements

- Design device concept

- Design system architecture

- Implement system

Project Detail

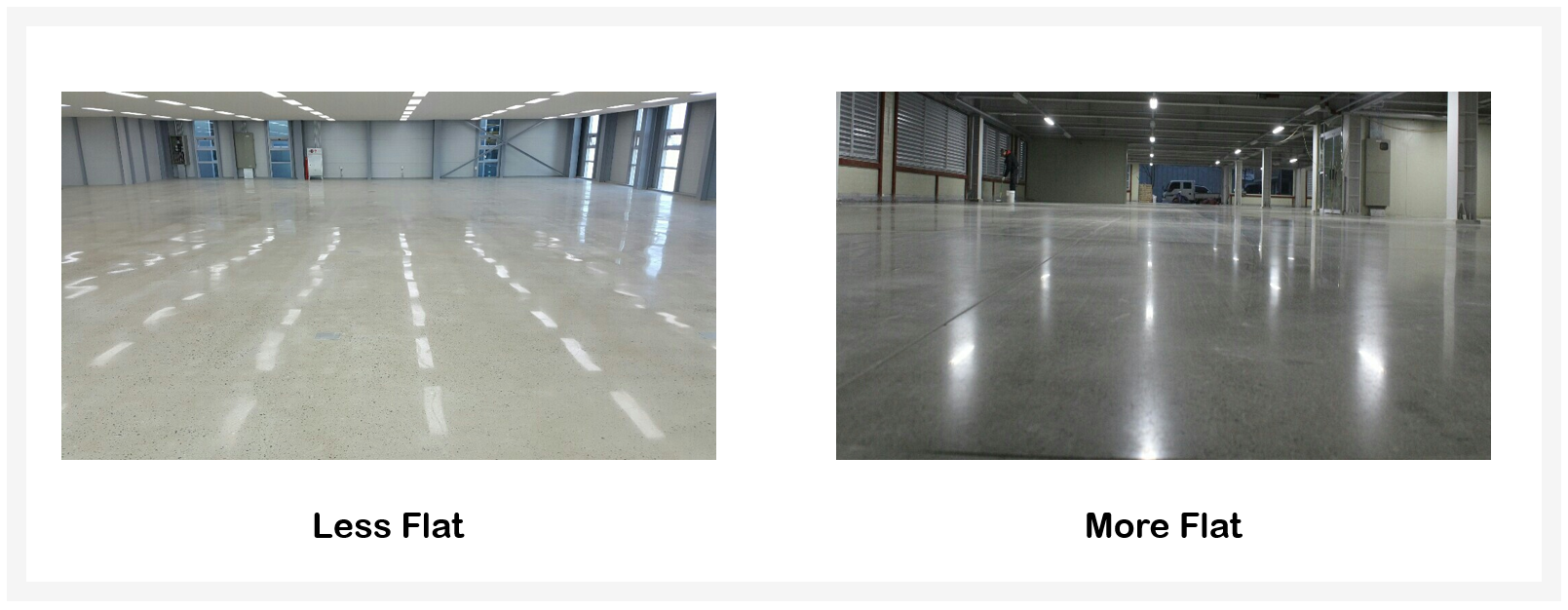

In many construction site, floor leveling is hard to handle perfectly. It is caused by problems including wrong concrete pouring and uneven base ground. Especially, this uneven floor makes issues such that floor coating becomes poor looking shapes and special facilities where strict environment is required (e.g. distribution center, precision manufacture) cannot have proper ground state to install equipment.

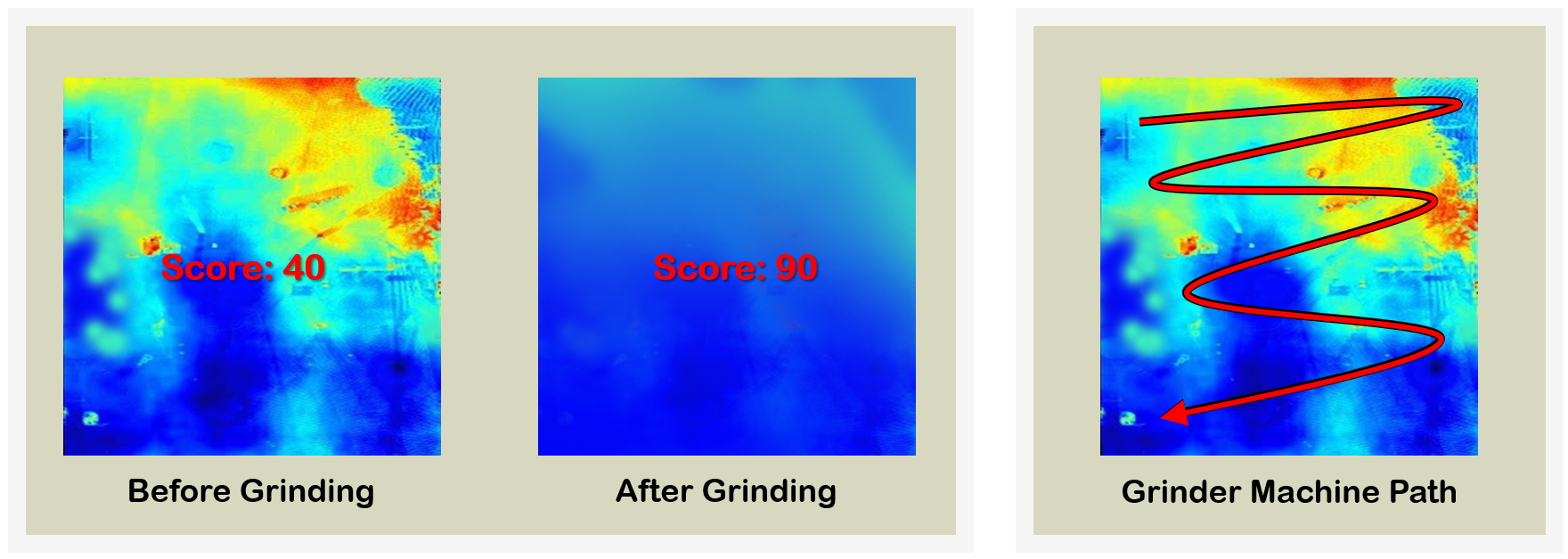

Many construction companies try to fix this problem by various methods. One of general solutions is to use grinding machine. Running grinding machine, operator needs to have sufficient experience to determine how much grinding should be done in order to make the ground even.

In this process, there are two drawbacks that

- Success of grinding depends on personal skill based on eye measurement

- There is no quantified measurement system on how much an operator levels the ground off

Thus, if there is a way to support flatness measurement task through quantifying atypical image data and visualizing data, work efficiency and reliability can be increased. I made a team with my friend and undertook to solve this problem.

Planning

Starting from this project, the final purpose that we want to achieve is to improve all procedures of floor leveling. Because it is hard to improve all procedures of floor leveling at once, we established three big stages. This project is just on the first stage of bigger plan. Briefly, we approach the goal by below methods

- Establish quantifying atypical data system

- Gather data

- Evaluate tasks

- Improve equipment

1. Measurement and Visualization

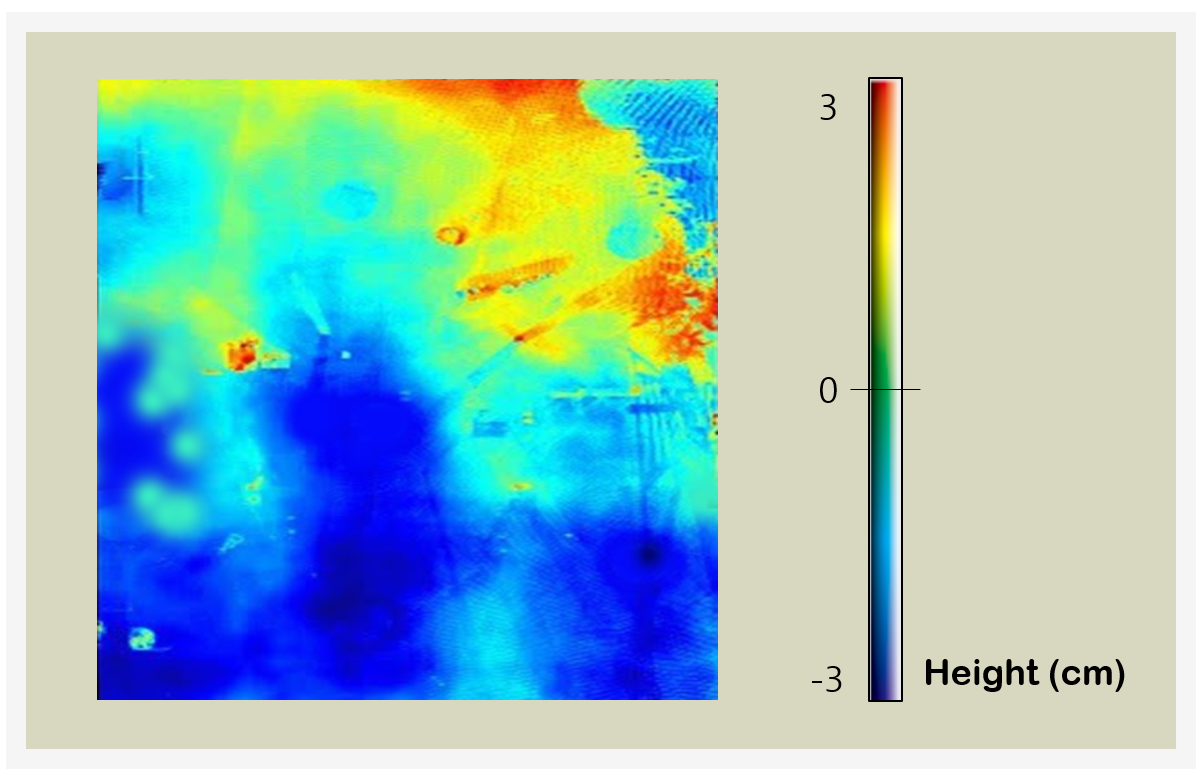

First of all, we need to acquire precise spatio map. Only if we obtain clear data, it is possible to advance the rest of procedure based on quantified indicator.

2. Gathering Field Data

If it is possible to provide clear spatio map data, gathering meaningful data from field is feasible. First, we can calculate score of flatness from measuring data via several evaluating standard of floor flatness. Second, we can evaluate results of field workers by analyzing difference of measured map data before task and after task.

Also, we are going to collect additional data including path of grinding machine in field, ground material and workers’ information.

Analyzing these data, we decide what the best result done by worker is and the best way to operate a grinding equipment. Furthermore, through the best method, it is possible to provide driving guidelines of grinding machine for field workers.

3. Improvement of Grinding Machine

From accumulated data, we expect to find improvable point of grinding machine because present machine has a shortage that it is hard to cover areas in detail. This process includes designing new machine and numerous experiments.

Requirements

At the beginning of project, my team investigated requirements from field workers at first. To acquire sufficient information, we interviewed in many ways.

How accurate should a sensor be?

There is no exact numerical criterion. In the present process, since most workers check flatness based on eye measurement, it might vary by people. But, I think that it is necessary for the sensor to be accurate enough to determine whether it would be flat enough to install precision equipment. It might be about 3mm.

☛ Requirements: Sensor should be able to check under 3mm.

How long does it takes to measure flatness?

Currently, we do not devote a lot of flatness measurement time. But as correct ground information map is important, we can put additional time and human resources if flatness measurement is needed extra process to measure and map ground information. We put a request to minimize measurement time as much as possible because there are other processes in the whole procedure.

☛ Requirements: Measurement time should be minimized as much as possible.

How much budget should be devoted to develop a device?

Average budget of procedure is about 0000 and assigned budget on usage of equipment is about 0000. So, we wish the price of measurement device about 0000.

☛ Requirements: Device development cost should be under 0000.

Research

There are many sensors used for obtaining space information. Since most of them have a positive correlation between price and accuracy, we need to find a compromise. As task sites can be both inside and outside, there is a huge possibility that sensors can be affected by variance of illumination condition. Therefore, photogrammetry was excluded in selection and we decided to start from Light Detection And Ranging(LIDAR) sensor because it has a reasonable price and accuracy.

Furthermore, to get spatial map, it is necessary to choose a method to build map by data from sensors. Thus, we study about Simultaneous Localization And Mapping(SLAM).